As the power circuit’s ability to convert energy improves, so does its power consumption. Additionally, numerous electronic components produce a lot of heat which creates issues with heat dissipation and necessitates the use of a tool for dissipating heat.

A device called a heat sink used to dissipate heat from readily heated electronic components found in electrical equipment. It is primarily made of bronze brass or an alloy of aluminum alloy in the form of plate sheets or multiple sheets. For instance, the computer’s CPU or center for processing should be extremely massive.

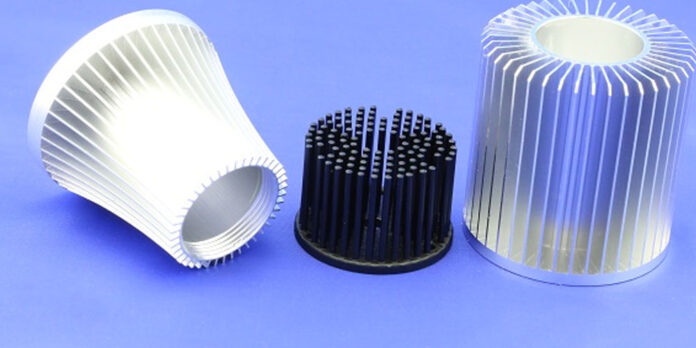

It is a heat sink is required for usage by the electric tube, line tube, power amplifier tube, and power the tube in TV. The outer peripheral surface of the base of the round heat sink is uniformly covered with heat dissipation fins, and each heat dissipation fin’s length extension direction is parallel to the base’s axis.

Structure of Round Heat Sink

The base’s exterior perimeter surface of the circular heat sink is uniformly covered with the direction of each heat dissipation fin’s length extension is parallel to the base axis.

The heating element is protected, the structure is straightforward, the heat dissipation effect is excellent, the region of heat dissipation is larger, the heat dissipation capacity is increased, effectively transmits the heat produced by the heating element. Thus the issue of failure brought on by the heating element overheating is avoided.

Objectives of Round Heat Sink

- Because some of a CPU’s components produce heat, a CPU is prone to overheating. Your CPU will burn or fry if you don’t use a heatsink since the heat produced by the components stays inside of it.

- The fact that electronic chips make up the majority of components makes them heat-absorbent.

- It is essential to have the heat sink since it keeps your CPU cool even when used for extended periods of time.

- It is made to absorb the heat produced by your CPU and then disperse it away from its internal parts.

Certain Benefits of Round Heat Sink

Round heat sinks, particularly those with omnidirectional properties and low airflow performance, provide unparalleled advantages in a variety of applications. They are therefore perfect for equipment that is mission-critical.

- Any direction can send airflow because of the omnidirectional property. Additionally, any alteration in airflow patterns (such as speed and direction) only has a minimal effect on how well they work.

- Our regular round pin heat sinks are composed of 1070 aluminum, which has a thermal conductivity that is significantly higher than that of 6063 and 6061 aluminum alloys.

- Cold-forged from pure aluminum, the round pin heat sinks have an incredibly high level of quality and thermal conductivity.

- The S807 series is suited for situations requiring modest airflow and natural convection.

- Applications requiring medium to high airflow are the focus of the S805 series.

- Standard dimensions range from 1515 (0.6′′x0.6′′) to 125100 mm (5′′x4′′), and from 10 to 30 mm in height.

- Heat sinks with a high aspect ratio can be customized and up to 250x200mm in size without the need for new tooling.

Last Wording

Aluminum alloys, the majority of which have high thermal conductivity values, are often used in the construction of round heat sinks. Although copper is significantly more expensive and denser than aluminum, it also absorbs heat more effectively and has better thermal conductivity. Copper heat sinks are used in many different applications and sectors, including power plants, HVAC systems, geothermal heaters and coolers, and electronic systems.